Transform Your Industry with the Power of Digital Twin

Unlock real-time visibility, immersive training, predictive insights, and smarter decision-making for factories, utilities, data centers and critical infrastructure.

Our Core Solutions

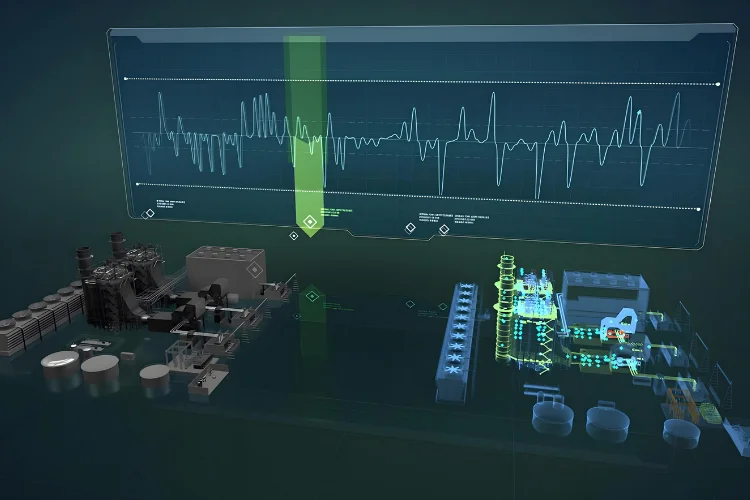

Digital Twin

Platforms

A dynamic mirror of your physical environment. Visualize your operations in real time, detect anomalies, simulate outcomes, and make proactive decisions.

- Real-Time Monitoring & Visualization

- Predictive Maintenance

- Asset Tracking & Energy Optimization

- 3D Plant & Equipment Modeling

AR/VR Training

Modules

Train your workforce without downtime. Our AR/VR-based modules deliver immersive, off-network training that boosts operational readiness and reduces human error.

- Equipment Operation & Fault Diagnosis

- Safety & SOP Training

- Offline VR Simulation

- Custom-Designed Training Programs

Predictive Maintenance & Performance Monitoring

Prevent failures before they happen. Our AI-powered analytics detect early signs of wear, inefficiency, and system anomalies helping you schedule maintenance proactively, reduce downtime, and extend the lifespan of critical assets.

- Early Fault Detection

- Downtime & Cost Reduction

- Asset Life Extension

- AI-Driven Performance Insights

Industries We Serve

We offer tailored Digital Twin and AR/VR training solutions across multiple verticals, addressing their unique challenges and accelerating their digital transformation journey:

Textiles & Apparel

Standardize operator training, reduce production losses, and enhance quality control across dyeing, stitching, and finishing with tailor-made digital twin solutions and immersive simulations.

Manufacturing

Streamline factory operations, optimize production lines, and deliver immersive training on complex machinery using real-time digital replicas and virtual simulations.

Oil & Gas

Enhance safety and asset reliability with digital twins that simulate remote operations, monitor equipment health, and enable virtual SOP and emergency training.

Power Plants & Substations

Gain real-time visibility into substations and transmission assets, ensure predictive maintenance, and use virtual training to improve operational awareness and grid resilience.

Data

Centers

Visualize IT infrastructure, optimize cooling systems and power flow, and train personnel in risk-free environments to ensure uptime, efficiency, and disaster preparedness.

Real Estate & Construction

Track construction progress, optimize site workflows, and visualize infrastructure projects using BIM-integrated digital twins and AR-based walkthroughs.

Results That Matter

- Increase in operational visibility

- Reduction in unexpected downtime

- Real-time fault alerts and early anomaly detection

- Consistent operator performance through virtual training

- Energy efficiency gains

- Proactive capacity planning with predictive insights

Who We Are

We are innovators in Digital Twin technology — transforming the way industries operate, train, and make decisions. Our platform creates intelligent digital replicas of your physical assets, delivering real-time data, predictive maintenance, and immersive AR/VR training for your workforce.

From power distribution networks to textile mills and data centers, we bring clarity, efficiency, and foresight to your operations.

Why Choose Us?

✅ Field-Proven Results – Backed by real-world projects in Pakistan and internationally

✅ Deep Engineering + Digital Expertise – Built by industry professionals for industry professionals

✅ Custom-Tailored Platforms – Adapted to your environment and goals

✅ Offline Capability – AR/VR modules that work without a live network

Ready to Start Your Digital Transformation?

Let’s build the digital backbone of your operations. Explore how our Digital Twin and AR/VR solutions can transform your efficiency, safety, and training.