Steel Warehouse Digital Twin System

The Steel Warehouse Digital Twin System is based on the physical entity of the steel warehouse, utilizing 3D modeling and digital twin technology to digitally reconstruct the production site. It integrates and merges the warehouse’s existing multi-source heterogeneous data to recreate real working scenarios in virtual space. Through real-time interaction between the physical and virtual environments, the system enables multi-angle, real-time 3D monitoring. This facilitates monitoring of warehouse tasks, inventory, personnel, vehicles, energy consumption, and alarm information management. Additionally, the vast amount of twin data generated during the virtual-physical interaction process is used to optimize decision-making in the production process.

Development

General System Functions

The general system functions module serves as the foundation for the application of the digital twin system. Its critical components include basic 3D interactive functions, layered management of 3D twin scenes, automated inspection path roaming, multi-level navigation maps, and the distribution of video surveillance points.

3D Twin Mapping

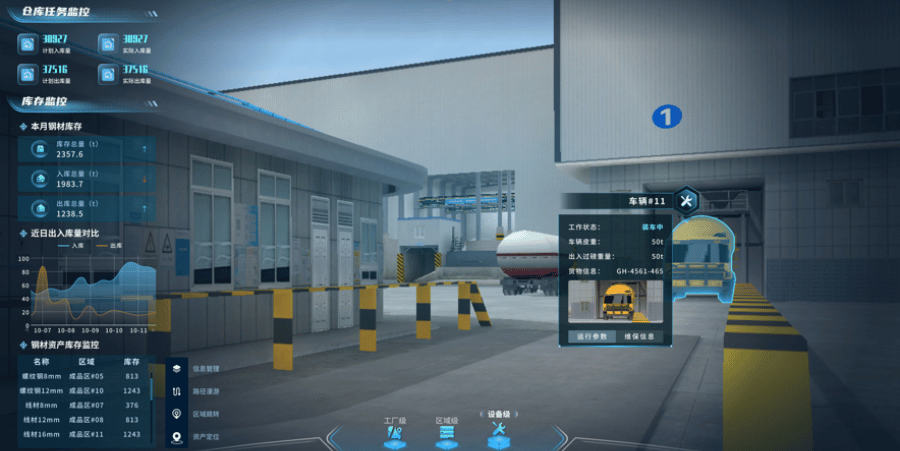

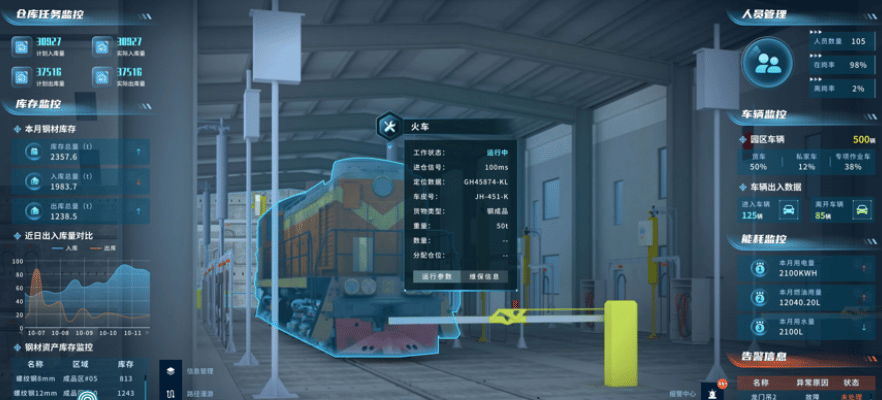

3D twin mapping is the core of the digital twin system. By digitally reconstructing the production site, it aims to link production activities in the virtual digital space with those in the physical space. The key components of the 3D twin mapping module include monitoring the operational status of freight trains, gantry cranes, loading and unloading vehicles, and freight vehicles.

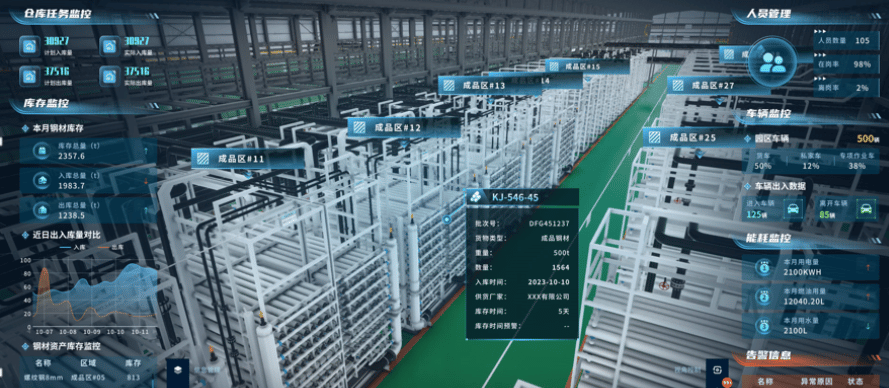

Inventory Management

The inventory management module, based on current warehouse location data, manages the data of the steel plant’s warehouse locations and steel asset positioning within the 3D twin scene. This facilitates transparent control of the steel plant’s inventory.

Safety Management

The safety management module focuses on the real-time control of personnel positioning and video surveillance data.

Business Monitoring

Business monitoring is the core application of the digital twin system. It can be used for monitoring the inbound and outbound movement of steel assets, steel asset inventory, equipment operational status, and equipment maintenance operations.

System functions

Warehouse Task Monitoring

Displays current inbound/outbound plan data and actual execution data, as well as the trends of inbound/outbound data over the past five days, allowing for a comparison of the volumes.

Inventory Monitoring

Shows the total steel inventory, total inbound volume, and total outbound volume for the current month.

Steel Asset Monitoring

Monitors the inventory levels and storage areas for each type of steel asset.

Personnel Management

Tracks the total number of warehouse personnel, on-duty rate, and off-duty rate, with an option to view more detailed information.

Vehicle Monitoring

Provides real-time information on the types, quantities, and operational statuses of vehicles within the yard, including freight trains, loading/unloading vehicles, and freight vehicles.

Energy Consumption Monitoring

Displays the current status of key energy consumption indicators through a ranking system.

Alarm Information

Pushes alarm messages in real-time via a form-based interface.

Equipment Management

Shows the operational status of equipment through floating windows. In case of a malfunction, an alarm is triggered. The system also tracks the real-time progress of equipment repairs and adjusts the repair status based on the maintenance work orders