Transforming the Future of Mining with Digital Twin Technology

Smart Mining for a Sustainable Future

Welcome to the future of mining, where cutting-edge digital twin technology transforms the way mines operate, ensuring safety, efficiency, and sustainability. Our integrated digital twin solutions empower mining enterprises to achieve intelligent, green, and low-carbon development, driving the industry toward a new era of high-quality growth. By leveraging real-time data, AI-driven insights, and automation, we enable mining enterprises to optimize every stage of their operations—from resource extraction to transportation, maintenance, and risk management.

What is a Digital Twin for Mining?

A digital twin for mining is a virtual replica of a physical mine, powered by advanced technologies such as artificial intelligence (AI), the Internet of Things (IoT), big data, and real-time data analytics. It enables comprehensive monitoring, predictive analysis, and intelligent decision-making across all aspects of mining operations, from production and safety to equipment maintenance and emergency response.

By creating a seamless connection between the physical and digital worlds, our digital twin solutions provide mining enterprises with unparalleled insights, enabling them to optimize processes, reduce costs, and enhance safety.

Our Solutions

Our Comprehensive Digital Twin Solutions

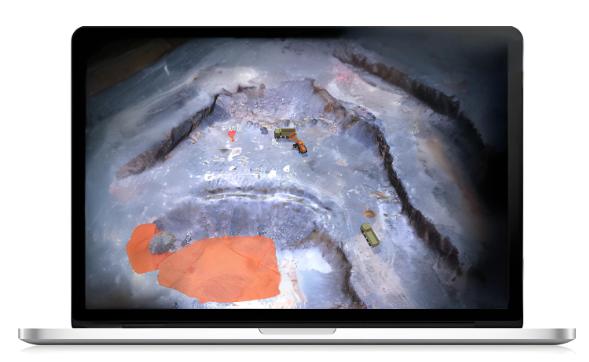

Mine Integrated Management and Control Platform

Our integrated platform leverages the power of the industrial IoT to unify production control, safety management, dispatching, and operational processes. It provides real-time visibility into mining operations, enabling proactive decision-making and reducing the risk of accidents.

Key Benefits:

- Real-Time Monitoring: Gain a holistic view of mining operations, including equipment, personnel, and environmental conditions. Eliminates data silos and enhances interoperability across mining operations.

- Enhanced Safety: Proactively detects hazards and ensures a safer mining environment. Reduce safety incidents by 15%-25% through AI-powered video surveillance and early warning systems.

- Operational Efficiency: Increase work efficiency by 15%-20% by digitizing manual processes and streamlining workflows.

- Cost Savings: Supports data-driven decision-making, reducing management costs by 10-15%.

Core Features:

Mine Process Management Center

Centralized management of attendance, assets, contracts, and performance.

Mine Production Control Center

Real-time digital mapping of mining environments, equipment, and personnel.

Mine Safety Control Center:

AI-driven visual analysis for detecting violations and ensuring compliance.

Mining Equipment Maintenance Center

Full lifecycle management of equipment maintenance and repairs.

Mining Intelligence Training Center

Virtual simulation training to improve skills and reduce technical barriers.

Mining Equipment Maintenance Center

Advanced Aerial Work Safety Control

Ensuring the safety of high-altitude operations is critical in mining. Our aerial work control platform combines GNSS, RTK, and UWB multi-mode fusion positioning with intelligent hardware to enhance safety and compliance. This system reduces human errors, standardizes work procedures, and enhances safety management for aerial operations.

Results You Can Expect:

- Operational Compliance: Full-process management of high-altitude work compliance through smart safety helmets and hooks.

- Real-Time Situational Awareness: 3D real-time monitoring of high-altitude operations using digital twin technology.

- Risk Reduction: Early detection of unsafe behaviors and conditions, such as improper use of safety equipment.

- Risk Reduction: Early detection of unsafe behaviors and conditions, such as improper use of safety equipment.

Core Features:

Smart Safety Equipment

Monitors Smart Helmets and hooks’ real time status and provides alarms for unsafe conditions.

Multi-Mode Fusion Positioning Helmet

Accurate indoor and outdoor positioning for workers.

Digital Equipment Managemen

Lifecycle management of safety equipment, from issuance to return.

Predictive Maintenance & Intelligent Fault Diagnosis

Powered by digital twins, our predictive maintenance system provides 24/7 equipment monitoring, reducing downtime and enhancing asset reliability. By integrating intelligent sensors and AI-driven analytics, mining enterprises can proactively address faults before they escalate into critical failures.

Key Benefits

Predictive Maintenance:

Reduce unplanned downtime by 20%-40% and maintenance costs by 20%-30%.

Enhanced Safety:

Improve safety production efficiency by 10%-20% through real-time equipment monitoring.

Data-Driven Decisions:

Provide actionable insights to optimize equipment performance and extend its lifespan.

Core Features:

Intelligent Sensing Equipment:

Real-time monitoring of vibration, temperature, and speed.

Fault Diagnosis and Prediction:

AI-powered diagnostic models for early detection of equipment failures.

Enterprise Fault Case Library:

Structured database of equipment faults and solutions for knowledge sharing.

Mine Emergency Response & Command System.

Our emergency response system integrates GIS mapping, IoT connectivity, and digital twin technology to provide real-time risk assessment, rapid response capabilities, and advanced incident management.

Key Benefits:

Real-Time Risk Prediction:

Monitor and predict potential risks using real-time data analytics.

Rapid Response:

Improve emergency response speed through integrated and centeralized communication and resource management.

Enhanced Collaboration:

Foster cross-departmental coordination for effective emergency handling.

Key Functionalities:

Optimized Resource Deployment:

Intelligent allocation of emergency resources based on AI-driven analytics.

Enhanced Communication & Coordination:

Facilitates seamless collaboration between emergency teams and site operators.

Why Choose Us?

- Proven Expertise: With a track record of successful implementations, we bring deep industry knowledge and technical expertise to every project.

- Customized Solutions: Our team of engineers and designers delivers tailored solutions to meet the unique needs of your mining operations.

- User-Centric Design: We prioritize ease of use, interactivity, and satisfaction in every product we develop.

- Future-Ready Technology: Our solutions are built on the latest advancements in digital twin technology, ensuring scalability and adaptability.

Join the future of smart mining—where intelligence meets efficiency, and sustainability meets profitability. Embrace digital twin technology and redefine the mining industry with unparalleled precision, safety, and innovation.